Description and objectives

Initial situation: Durability vs. recyclability

Highly stressed electronics, such as control systems for electric drives or intelligent measurement systems, are usually coated or encapsulated to protect them from environmental influences. These precautions make repair or recycling virtually impossible. There is a typical trade-off between longevity and recyclability of electronic components. This is illustrated by the following figures: in 2019, 53.6 million tons of electronic waste will be generated worldwide, of which only 20 percent will be recycled.

There are currently no processes that go beyond manual removal of the applied encapsulants. Components with a silicon-based protective coating can only be thermally recycled, which is neither economical nor sustainable. The need for sustainable, robust and selective decoating processes is growing in many industries, such as wind power, shipbuilding, aerospace and e-mobility.

The project in brief: Implementing Repair and Recycling Applications

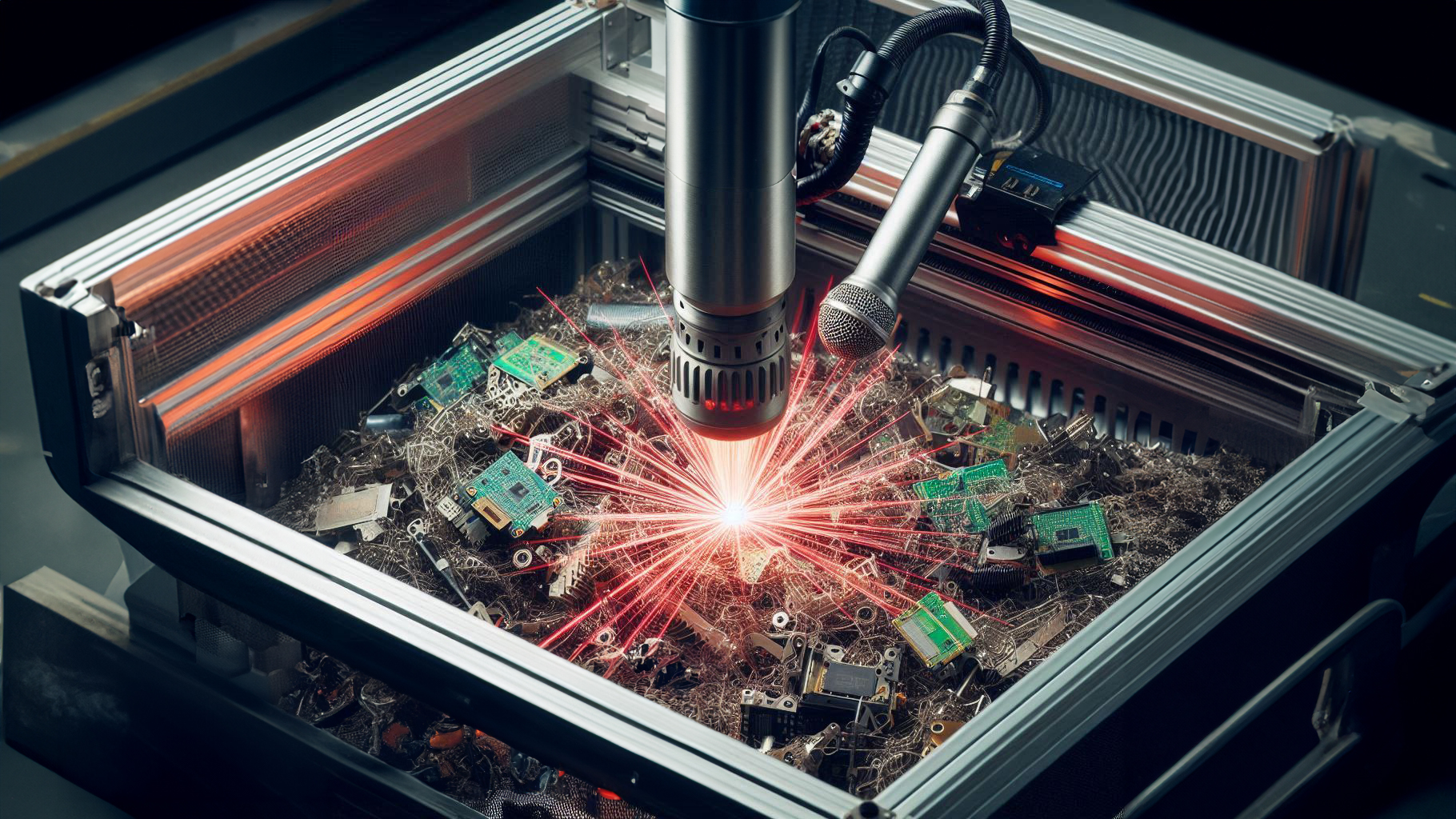

Laser ablation processes have already proven themselves in various industrial applications. However, complete and selective laser ablation of surfaces with 3D contours, high manufacturing tolerances and hybrid material combinations is not possible due to fixed process parameters. Defects or damage to the base material often occur due to the necessary focusing of the laser beam, reflections on inclined surfaces or due to the strong dependence of the interaction with the treated material.

With Rapid-KI, the project consortium aims to develop new processes for decoating electronic components by laser ablation in order to use them for recycling applications with the aim of making electronic waste recyclable and sustainable. Companies in the sensor, home appliance and consumer electronics industries will be the main beneficiaries of the new processes.

Project Goals: Innovation in process control

The described approach requires a change from pure sensor data acquisition to process control for highly dynamic laser processes. The planned research goals include

- Automatic path adaptation for 3D contours based on scanning interferometry

- Acoustic process control using AI evaluation

- Synthetic generation of acoustic training data to improve the acoustic AI model

- Development of a control loop for inline adjustment of laser parameters based on acoustic signals.

Fraunhofer Institute for Digital Media Technology IDMT

Fraunhofer Institute for Digital Media Technology IDMT